Driving

Automotive

Innovation

IATF 16949-certified manufacturing partner delivering precision components for ICE, hybrid, and electric vehicles. Zero-defect quality with global OEM and Tier 1 supplier experience.

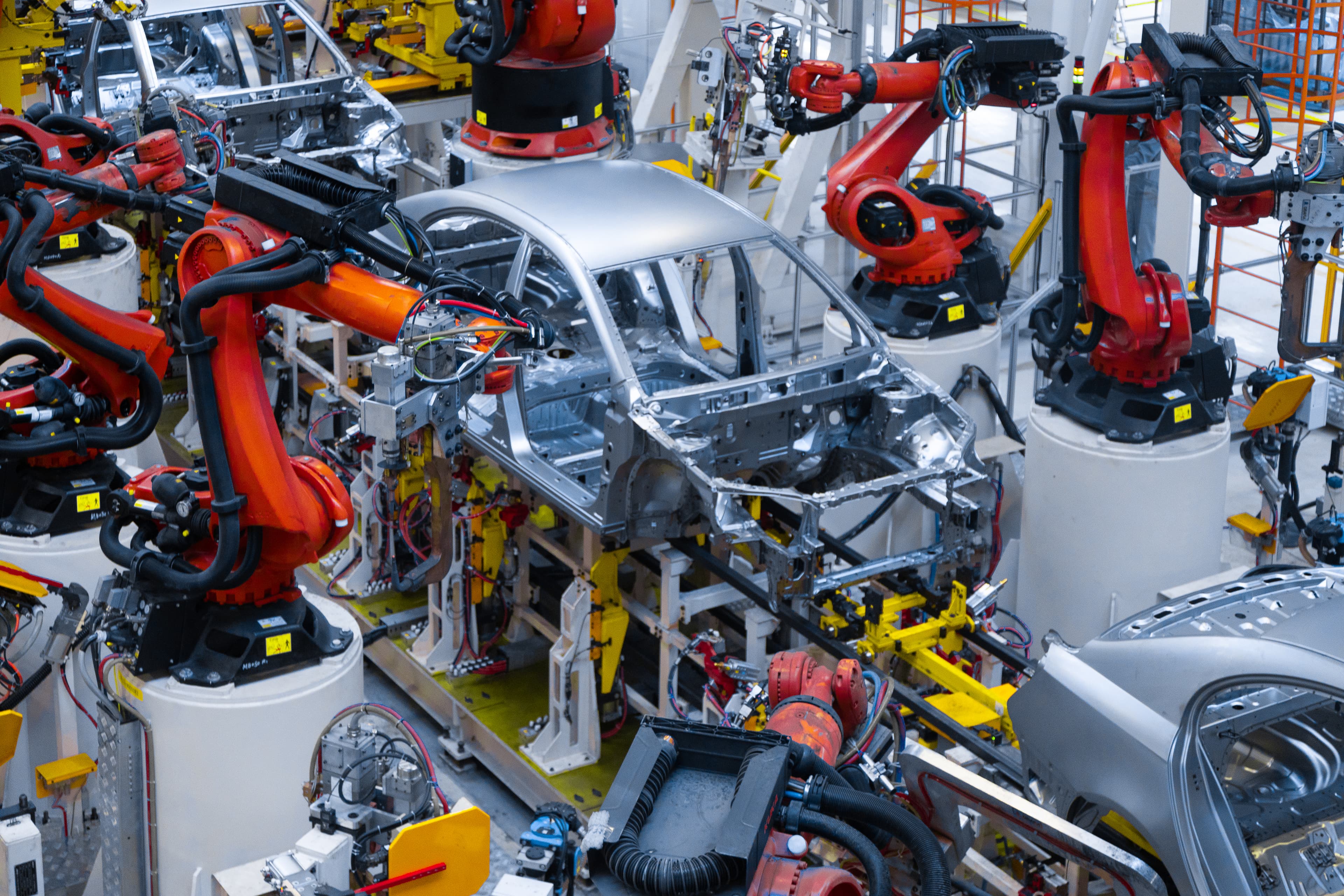

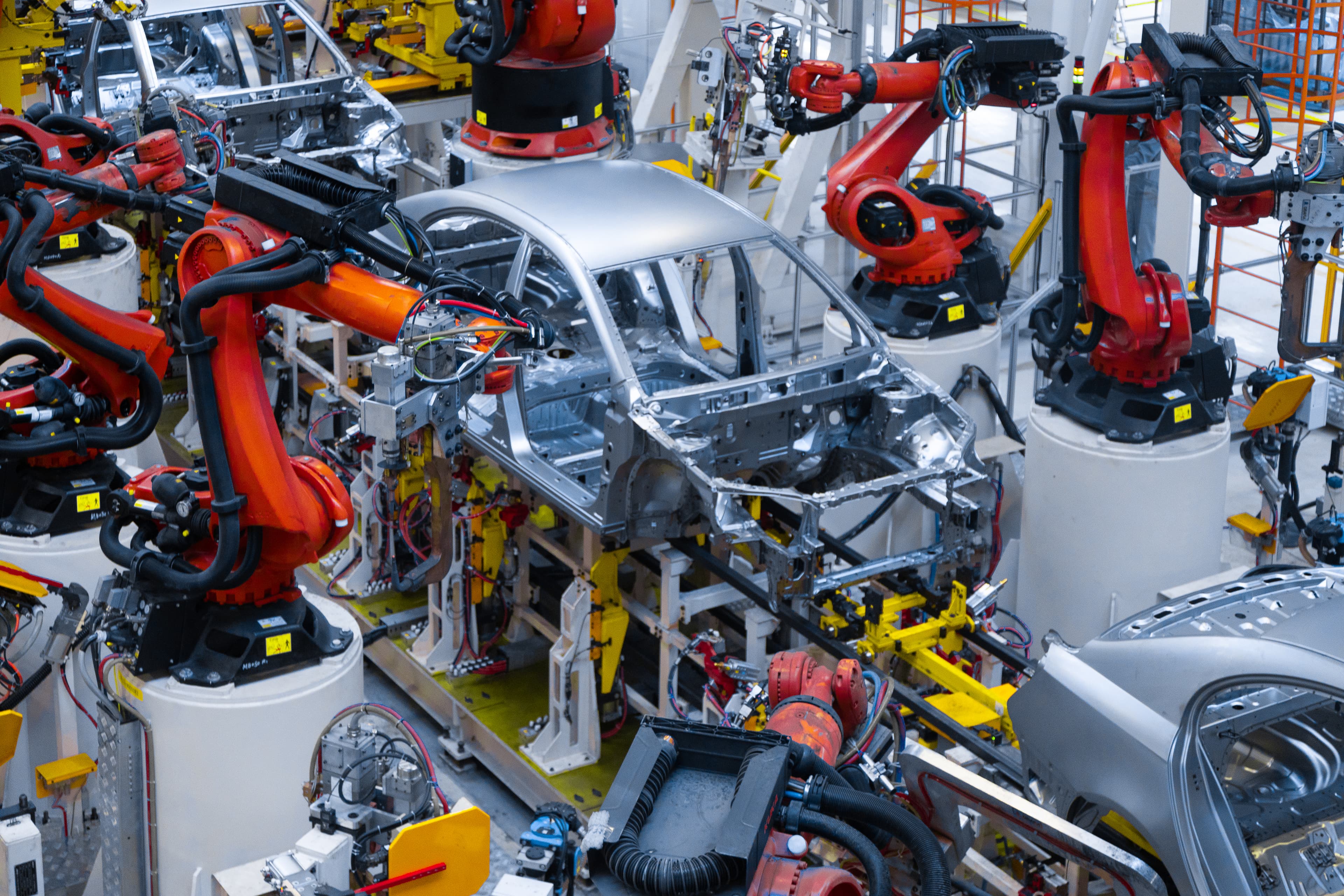

Precision Manufacturing for the Automotive Industry

Tour our IATF 16949-certified facility where advanced automation, precision machining, and rigorous quality systems deliver components that meet the demanding requirements of global automotive OEMs.

Engineered for Automotive Excellence

For over three decades, we have partnered with the world's leading automotive OEMs and Tier 1 suppliers to deliver precision-engineered components that meet the industry's most demanding quality and delivery requirements.

From traditional powertrain components to cutting-edge EV battery systems and motor housings, we provide complete manufacturing solutions with PPAP documentation and zero-defect quality.

OEM Approved

Trusted by global automakers

From APQP to Production

APQP Planning

Advanced Product Quality Planning with design FMEA, process flow, and control plan development

Tooling & Validation

Tool design, prototype builds, and run-at-rate validation to meet OEM timing requirements

PPAP Submission

Complete Production Part Approval Process documentation with MSA, capability studies, and sample submission

Series Production

High-volume manufacturing with SPC monitoring, error-proofing, and continuous improvement

Logistics & Support

JIT/JIS delivery, EDI integration, and dedicated customer support with 8D problem solving

Full-Spectrum Automotive Manufacturing

End-to-end manufacturing solutions from prototype through high-volume production. IATF 16949 quality at every step with complete PPAP documentation.

Request a QuotePrecision CNC Machining

High-volume CNC turning, milling, and multi-axis machining for engine, transmission, and drivetrain components with PPAP documentation

Stamping & Press Work

Progressive die stamping, deep drawing, and metal forming for body panels, brackets, and structural components

Die Casting & Forging

Aluminum and zinc die casting, hot and cold forging for lightweight powertrain and chassis components

EV Components

Battery enclosures, motor housings, power electronics cooling systems, and high-voltage connector assemblies

Assembly & Integration

Complete sub-assembly services with automated fastening, adhesive bonding, and in-line quality verification

Surface Engineering

E-coating, powder coating, zinc plating, and specialized automotive coatings meeting OEM corrosion specs

Frequently Asked Questions

We maintain all certifications required by global automotive OEMs and Tier 1 suppliers:

- IATF 16949:2016 certified with zero major nonconformances

- ISO 14001:2015 environmental management certification

- VDA 6.3 process audit qualified for German OEM programs

- Customer-specific certifications for Ford, GM, Toyota, VW, and more

Yes, we have invested significantly in EV-specific capabilities:

- Battery enclosure machining and assembly with thermal management integration

- Electric motor housings with precision bore tolerances and concentricity

- High-voltage connector and busbar manufacturing with safety protocols

- Power electronics cooling plates with complex internal channel machining

We provide complete PPAP packages to all 18 elements as required:

- Design records, engineering change documents, and customer approval

- Process FMEA, control plans, and MSA studies (Gage R&R)

- Dimensional results, material test reports, and performance testing

- Part submission warrant (PSW) with full capability studies (Cpk > 1.67)

Our flexible manufacturing supports the full range of automotive volumes:

- Prototype and pre-production builds with rapid tooling options

- Low-volume specialty and performance vehicle components

- Medium-volume production runs of 10,000-100,000 units annually

- High-volume programs exceeding 1 million parts per year with dedicated lines

Our quality systems are designed for automotive-grade zero-defect performance:

- Error-proofing (Poka-Yoke) integrated into all manufacturing processes

- In-line vision systems and automated gauging for 100% inspection

- SPC monitoring with real-time alerts and automatic process adjustment

- Layered process audits and daily quality reviews with containment protocols

We produce critical components across all major automotive systems:

- Powertrain: engine blocks, cylinder heads, transmission cases, and differential housings

- Chassis: control arms, knuckles, subframes, and suspension components

- Body: structural brackets, door hinges, seat frames, and interior trim

- EV: battery trays, motor housings, inverter enclosures, and charging components

Engineered for Better Performance.

Get expert guidance to improve design, efficiency, and overall product quality.